Fiirsanaanta emulsion-ka saxda ah oo joogto ah ayaa ah tiirka tayada badeecada, hufnaanta shaqada, iyo kaydinta qiimaha.Mitirrada feejignaanta EmulsionamaEmulsion fiirsashada kormeerayaashaBixi xogta waqtiga-dhabta ah si kor loogu qaadosaamiga isku dhafka emulsion, hubinta waxqabadka joogtada ah iyo u hoggaansanaanta heerarka warshadaha. Baadh sida kor loogu qaadocabbirka fiirsashada emulsionIsku dhafka saliidda iyo emulsion-ka biyaha, oo bixiya aragtiyo la taaban karogeeddi-socodyada qaboojinta duubista.

Muhiimadda Isku-ururinta Emulsion

Emulsions, isku dhafka saliidda iyo biyaha ee lagu dejiyo emulsifiers, ayaa lagama maarmaan u ah hababka roodhida qabowga iyo soosaarka daamurka. Emulsions waxaa loo isticmaalaa in lagu subko oo lagu qaboojiyo birta marka la duubo qabow.

Wareegga qabow, emulsions waxay saliideeyaan oo qaboojiyaan birta inta lagu jiro duubista, hubinta tayada dusha sare iyo saxnaanta cabbirka. U-fiirsashada emulsion-ka ee aan joogtada ahayn waxay u horseedi kartaa cillado, xirashada qalabka, ama u hoggaansanaan la'aanta deegaanka. Mitirrada fiirsashada Emulsion waxay bixiyaan la socodka wakhtiga dhabta ah si loo ilaaliyo saamiga ugu fiican ee saliidda biyaha iyadoo la dhimayo qashinka iyo kor u qaadista waxtarka. Waa hab wax ku ool ah oo looga hortagayo xagashada dusha sare ama la duubo kulaylka iyadoo la ilaalinayo saamiga isku dhafka emulsion ee 2% -10% ka kooban saliidda.

Caqabadaha Kormeerka Emulsion-dhaqameedka

Hababka dhaqameed ee cabbiraadda fiirsashada emulsion waa waqti badan oo u nugul khaladaadka. Muunad-bixinta khadka tooska ah iyo falanqaynta shaybaadhka ayaa sidoo kale qaban kari waayay isbeddello firfircoon. Intaa waxaa dheer, faragelinta gacanta waxay kordhisaa kharashka shaqada iyo wakhtiga dhimista, ka dibna guud ahaan wax soo saarka dheeraad ah.

Qiyaasta Isku-ururinta Emulsion ee wax ku ool ah

Mitirrada Xoojinta Emulsion Inline

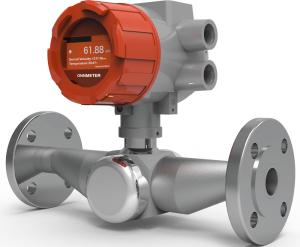

Mitirrada feejignaanta EmulsionIsticmaal tignoolajiyada horumarsan sida ultrasonic si loo cabbiro saamiga saliidda emulsion waqtiga dhabta ah. Qalabkan ayaa si toos ah loogu rakibay dhuumaha ama taangiyada, iyagoo bixinaya xog joogto ah iyada oo aan la joojin wax soo saarka. Waxay ku qiyaasaan xawaaraha codka iyaga oo cabbiraya wakhtiga gudbinta hirarka dhawaaqa ee isha ishaarada iyo qaataha ishaarka. Habkan cabbiraadda ma saameynayso dhaqdhaqaaqa, midabka iyo hufnaanta dareeraha, hubinta kalsoonida aadka u sarreeya. Isticmaalayaashu waxay gaari karaan saxnaanta cabbirka 0.05% ~ 0.1%. Mitirka fiirsashada ultrasonic ee badan ee shaqaynaysa ayaa awood u leh inay cabbirto Brix, nuxurka adag, walxaha qalalan ama ka joojinta.

Faa'iidooyinka Cabbiraadda Soo-ururinta Khadka Tooska ah

Mitirka-fiirsashada emulsion-ka ee khadka ayaa bixiya faa'iidooyin dhowr ah:

- Jawaab-celinta-waqtiga-dhabta ah: Xogta degdegga ah waxay ogolaataa in si degdeg ah wax looga beddelo saamiga saliidda biyaha, taasoo ka hortagaysa leexinta habka.

- Hawlgalka aan Duulaanka ahayn: Mitirka fiirsashada Ultrasonic uma baahna muunad, yaraynta khataraha faddaraynta.

- Saxnaanta Sare: Waxay xaqiijisaa sifooyinka emulsion joogto ah, oo muhiim u ah tayada alaabta ee duubista qabow.

- Kala duwanaansho: Ku habboon noocyo kala duwan oo emulsion ah, laga bilaabo saliidaha ilaa xidhayaasha asphalt.

Ultrasonic Emulsion Concentration Monitoring

Ultrasonic emulsion fiirsashada la socodka waxay u taagan tahay awoodeeda aan fiicneyn, ee saxda ah, gaar ahaan hababka qaboojinta duubista. Marka la cabbiro xawaaraha hirarka dhawaaqa iyada oo loo marayo emulsion-ka, kormeerayaashani waxa ay xidhiidhiyaan xawaaraha iyo feejignaanta emulsion-ka, oo aanay saamaynaynin arrimo ay ka mid yihiin midabka ama korantada.

Tani waxay ka dhigaysaa inay ku habboon yihiin jawi firfircoon halkaas oo emulsions ay ku xiran yihiin heerkulka ama isbeddelka halabuurka. Farsamadani waxay sidoo kale taageertaa sida loo isku daro saliidda iyo emulsion-ka biyaha iyadoo la siinayo xogta si loo hagaajiyo xaaladaha isku-dhafka, yaraynta khatarta kala-soocidda wajiga.

Isku-duubnida Emulsion ee Geedi socodka Qabow Rolling Mill

Gudahageeddi-socodyada qaboojinta duubista, emulsions waxay u adeegaan sidii saliidaha iyo qaboojiyaha, yaraynta khilaafka u dhexeeya duubabka iyo meelaha biraha ah iyadoo ay baabi'inayso kulaylka. Ilaalinta sida ugu fiicansaamiga saliidda emulsion(sida caadiga ah 4% -6% birta duuban) waa muhiim si looga hortago cilladaha dusha sare iyo xirashada qalabka.Emulsion fiirsashada kormeerayaashaBixi xogta waqtiga-dhabta ah si loo hagaajiyo ku-darka biyaha ama saliidda, hubinta sifaynta joogtada ah.

Sida Loo Wanaajiyo Cabbiraadda Isku-darka Emulsion-ka ee Isku-dhafka Saliidda iyo Biyaha Biyaha

Tallaabada 1: Dooro mitirka xoogga saarista Emulsion ee saxda ah

Si wax looga qabtosida loo hagaajiyo cabbirka fiirsashada emulsion ee isku dhafka saliidda iyo emulsion, ku bilow adiga oo dooranaya mitir ku habboon warshadahaaga. Waayogeeddi-socodyada qaboojinta duubista,mitirka fiirsashada emulsion ultrasonicwaxay ku fiican yihiin sababtoo ah naqshadooda saxda ah iyo kuwa aan qallafsaneyn. Tixgeli arrimo ay ka mid yihiin nooca emulsion-ka, xaaladaha hawlgalka, iyo la-qabsiga nidaamyada xakamaynta ee jira.

Talaabada 2: Isku-dhafka Nidaamyada Automation-ka

Is dhexgalka aan kala go 'lahayn ee nidaamyada PLC ama DCS ayaa muhiim u ah waqtiga dhabta ahcabbirka fiirsashada emulsion. Wareegyo jawaab celin oo toos ah ayaa hagaajiyaisku qas saliid iyo emulsion biyahahabka, ilaalinta la doonayosaamiga saliidda biyaha.

Talaabada 3: La Soco oo Hagaajin Xaaladaha Isku Dhaaf

Hagaajintasida loo isku daro saliidda iyo emulsion-ka biyahawaxay u baahan tahay la socodka halbeegyada isku dhafka ah sida heerka xiirta, heerkulka, iyo fiirsashada emulsifier.Emulsion fiirsashada kormeerayaashaBixi xogta si loo hagaajiyo doorsoomayaashan, hubinta xasilloonidaemulsions isku dhafan.

Talaabada 4: Tareen Shaqaalaha oo Ilaaliya Qalabka

Wax ku ool ahcabbirka fiirsashada emulsionwaxay ku tiirsan tahay hawl-wadeeno tababaran oo tarjumi kara xogta waqtiga-dhabta ah oo samayn kara go'aamo xog ogaal ah. Habaynta joogtada ah eemitirka feejignaanta emulsionwaxay xaqiijisaa saxnaanta, gaar ahaan meelaha qallafsan sida warshada duubista qabow. Jadwalka dayactirku waa inuu la jaanqaadaa wareegyada wax soo saarka si loo yareeyo wakhtiga dhimista.

FAQsKu saabsan Cabbirka Xoog-ururinta Emulsion

Waa maxay Doorka Mitirrada Isku-ururinta Emulsion ee Wareegga Qabow?

Mitirrada feejignaanta Emulsionhubi saxsaamiga saliidda emulsiongudahageeddi-socodyada qaboojinta duubista, hagaajinta saliidda iyo qaboojinta. Waxay yareeyaan cilladaha dusha sare, xirashada qalabka, iyo qashinka emulsion, hagaajinta tayada iyo waxtarka.

Sidee Kormeerayaasha Isku-ururinta Emulsion u wanaajiyaan Wax soo saarka Asphalt?

Emulsion fiirsashada kormeerayaashaxasillooniemulsions isku dhafanee wax soo saarka asphalt, hubinta viscosity habboon iyo adhesion. Waxay yareeyaan isticmaalka biyaha waxayna ka hortagaan burburka emulsion, kor u qaadida adkeysiga wadada iyo kaydinta kharashka.

Waa maxay faa'iidooyinka Kharashka ee Cabbirka Isku-ururinta Emulsion-Waqtiga-Dhabta ah?

Waqtiga dhabta ahcabbirka fiirsashada emulsionwaxay yaraynaysaa qashinka alaabta, isticmaalka tamarta, iyo wakhtiga dhimista. Gudahageeddi-socodyada duubka qabow, waxay badbaadin kartaa 5% -10% kharashka emulsion, halka kuwa wax soo saara ee asphalt ay soo sheegaan 5% -8% kaydinta biyaha iyo isticmaalka emulsifier.

Qiyaasta feejignaanta Emulsionwaa rukunka hufnaanta iyo tayada gudahageeddi-socodyada qaboojinta duubista. Ka faa'iidaysigamitirka feejignaanta emulsioniyoEmulsion fiirsashada kormeerayaasha, soo saarayaashu waxay ku gaari karaan xakameyn sax ah oo ku saabsansaamiga saliidda biyahaiyosaamiga isku dhafka emulsion, hubinta xasilloonidaemulsions isku dhafan.

Qalabkan ayaa wax ka qabtasida loo hagaajiyo cabbirka fiirsashada emulsion ee isku dhafka saliidda iyo emulsion, bixinta kaydinta kharashka, tayada alaabta oo la xoojiyay, iyo u hoggaansanaanta sharciga. Haddii aad tahay warshad-shiid kiimikaad qabow ama soo saare asphalt, la socodka wakhtiga dhabta ah ayaa beddela hawlahaaga. La xidhiidh kooxdayada si aad u habaysanmitirka fiirsashada emulsionxal ama booqo website-keena si aad u hesho la tashi bilaash ah maanta!

Waqtiga boostada: Jul-11-2025