Qiyaasta heerka socodka saxda ah ayaa muhiim u ah ilaalinta tamarta hufan iyo horu-marinta warshadaha iyo sida dhirta kiimikada. Dooro hab ku habboon ayaa muhiim ah iyadoo loo eegayo nooca dareeraha, shuruudaha nidaamka, iyo xitaa codsiyada gaarka ah. Astaamaha dareeraha waxay ku kala duwan yihiin viscosity, cufnaanta, heerkulka, qiimaha pH iyo awoodda daxalka. Waxaa intaa dheer, xaaladaha nidaamka sida cadaadiska, nidaamka socodka iyo deegaanka la dabaqay waa in lagu xisaabtamaa.

Waa maxay Heerka socodka?

Heerka socodka waxaa loola jeedaa tirada dareeraha soo diraya iyada oo loo marayo dhibic halkii halbeeg. Waxa lagu cabbiraa halbeeg sida litirkii ilbiriqsikii ama gallon daqiiqaddii sida caadiga ah. Waa halbeeg muhiim ah oo ku saabsan injineernimada hydraulic iyo sayniska caafimaadka. Injineerada ayaa awood u leh inay helaan aragtiyo ku saabsan nidaamka dareeraha ah, gaar ahaan ka qayb qaadashada wanaajinta habaynta warshadaha iyo samaynta go'aamo xog ogaal ah.

Qodobbada Saamaynaya Heerka Socodka

Fahamka arrimaha saameeya heerka socodka waa shardiga ah in la doorto xaaladda ugu wanaagsan ee cabbirka heerka socodka. Nooca dareeraha, hantida, nidaamka socodka, heerkulka, cadaadiska, cabbirka tuubada, qaabeynta iyo shuruudaha rakibidda ayaa ah dhammaan arrimaha saameynaya heerka socodka.

Aqoonso Nooca Dheecaannada

Waa muhiim in la aqoonsado dhexdhexaadiyaha aad la macaamilayso. Tignoolajiyada cabbiraadda socodka gaarka ah waa in loo qaataa si ka duwan dareere kasta. Tusaale ahaan, gaasaska waa la cadaadin karaa laakiin dareerayaashu ma sameeyaan; cufnaanta uumiga waa doorsooma. Dheecaannada viscosity-ka sarreeya sida saliidda waxay ku faafiyaan dhuumaha si ka duwan dareeraha viscosity hoose sida biyaha. Waa lagama maarmaan in mulkiilayaasha iyo injineerada dhirta kala duwan ay doortaan tignoolajiyada ku habboon cabbirka saxda ah iyo xakamaynta saxda ah.

Sidee loo cabbiraa heerka socodka?

Mitirrada qulqulka mugga ama mass socodka

Samaynta doorashada inta u dhaxaysa cabbirka mugga ama cabbirka qulqulka tirada badan waa tallaabo lagama maarmaan ah ka hor inta aan la wanaajin saxnaanta nidaamyada dareeraha.Mitirrada qulqulka muggawaxay ku fiican yihiin dareerayaasha cufnaanta inay ku sugnaadaan heer xasiloon, gaar ahaan inta badan dareerayaasha iyo gaaska ku jira nidaamka habaynta.Cabbirka qulqulka tirada badanwaa lagama maarmaan haddii ay dhacdo cufnaanta isbeddelka heerkulka iyo cadaadiska. Sababtan awgeed, mitirka socodka mass ayaa lagu dabaqaa si loo qabto wadarta tirada walxaha maraaya hal dhibic halkii halbeeg.

Dooro mitirka socodka ku habboon

Mitirrada socodka Volumetric

Mitirka socodka Ultrasonic

Mitirka socodka magnetic

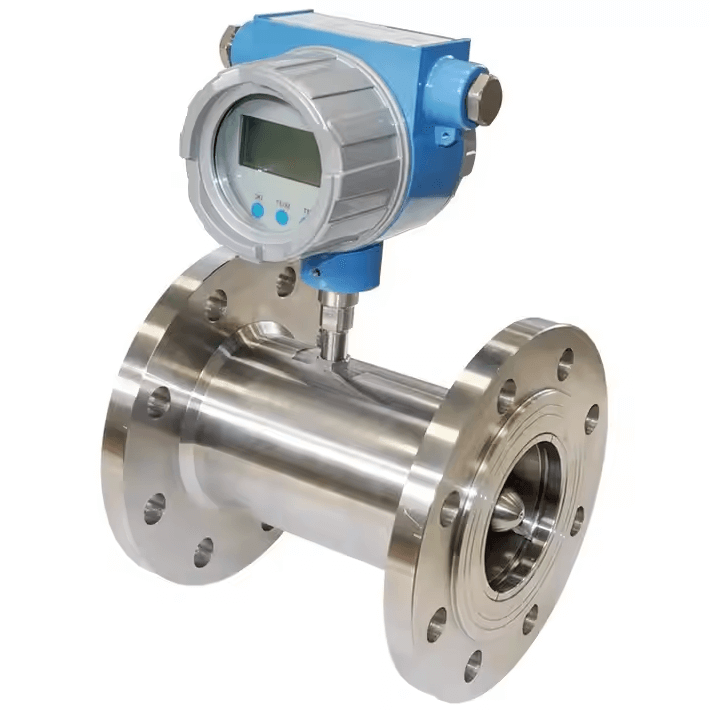

Mitirka socodka Turbine

Mitirrada socodka Mass

Riix halkan oo arag macluumaad dheeraad ah oo ku saabsannoocyada mitir socodka.

Cabbir nambarka Reynolds (Haddii loo baahdo)

Cabbir nambarka Reynolds si aad u saadaaliso nidaamka socodka ku salaysan xawaaraha dareeraha, cufnaanta, viscosity iyo dhexroorka tuubada, ha ahaato laminar ama qas. Dareeraha waxaa loo tixgelin karaa laminar marka Reynolds ay ka hooseeyaan 2,000 qiyaastii. Si kale haddii loo dhigo, dareeruhu waa qas marka Reynolds ay ka sarreeyaan 4,000. Ka hubi nidaamka socodka nambarada Reynolds muhiimada waxqabadka iyo saxnaanta mitirada socodka.

Rakibaadda mitirka socodka

Ku rakibida mitirka socodka qayb toos ah si loo leexiyo madhan, baallayaasha iyo carqaladaha kale ayaa ah xalka ugu fiican ee waxqabadka ugu fiican, kaas oo socodka dareeruhu uu ahaanayo mid joogto ah oo lebbisan. Marka lagu daro qodobbada kore, toosintu waa sabab kale oo saameynaysa saxnaanta mitirka khalkhalgelinta socodka ee ay kiciso nooc kasta oo khaldan. Qaladaadka shaqada iyo waxtarka waa la wanaajin karaa inta ugu badan ee suurtogalka ah haddii dhammaan faahfaahintaas lagu xisaabtamo rakibidda.

Fuli Kala-soocidda lagama maarmaanka ah ka hor Cabbirka Joogtada ah

Qalabaynta ayaa lama huraan u ah si loo dammaanad qaado saxnaanta mitirkaaga socodka, gaar ahaan codsiyada warshadaha halkaasoo saxnaanta ay muhiim tahay. Samaynta jaangooynta waxay ku lug leedahay isbarbardhigga wax-soo-saarka mitirka iyo is-habaynta sida loogu baahan yahay si loo hubiyo in akhrisku ku jiro heerarka dulqaadka ee la aqbali karo. Qalabaynta joogtada ahi kaliya ma ilaaliso saxnaanta mitirka laakiin sidoo kale waxay kordhisaa nolosheeda shaqo, iyada oo ka hortagaysa khaladaadka qaaliga ah ama waxtar la'aanta xakamaynta habka.

Waqtiga boostada: Oct-16-2024