Tayada joogtada ah ayaa muhiim u ah wax soo saarka daroogada ee soo saarista daawooyinka. Habka crystallization-ka warshadaynta iyo xakamaynta ayaa door muhiim ah ka ciyaara gaaritaanka yoolalkan, gaar ahaan ilaalinta nadiifnimada, qaabka crystallization, iyo qaybinta cabbirka walxaha daawooyinka firfircoon (APIs). Korjoogteynta Crystallization, gaar ahaan warshadaha dawooyinka, waxay u suurtagelisaa soosaarayaasha inay hagaajiyaan hababka, yareeyaan kharashaadka, oo ay la kulmaan heerarka sharci ee adag. Iyada oo tignoolajiyada horumarsan sida la socodka kristallization ultrasonic, helitaanka xogta-waqtiga dhabta ah ayaa bedelay sida warshadaha dawooyinka u maareeyaan hababka crystallization adag.

Ahmiyada Kormeerka Crystallization ee Dawooyinka

Crystallization waa tallaabo muhiim u ah soo saarista dawooyinka, oo loo isticmaalo sifaynta iyo samaynta API-yada. Nidaamku wuxuu go'aamiyaa sifooyinka jirka iyo kiimikaad ee badeecada ugu dambeysa ee dawada, oo ay ku jiraan milanka, noolaha, iyo xasilloonida. Cabbirka crystal-ka ee aan is-waafaqsanayn, qaabka, ama polymorphism-ka waxay u horseedi kartaa kala duwanaansho waxtarka daroogada, taasoo keenaysa khataraha badbaadada bukaanka iyo u hoggaansanaanta sharciga. La socodka kristalisaynta dawooyinka waxay hubisaa in guryahan la xakameeyo wakhtiga dhabta ah, iyadoo la yareynayo kala duwanaanshiyaha Dufcaddii iyo hubinta wax soo saarka tayada sare leh.

Caqabadaha ka jira Geedi-socodyada Crystallization-ka Dhaqanka

Hababka crystallization dhaqameed waxay inta badan ku tiirsan yihiin muunad offline iyo falanqaynta shaybaadhka, kaas oo soo bandhigaya dib u dhac iyo kordhinta khatarta khaladaadka. Hababkani waxay halgan ugu jiraan sidii ay u qaban lahaayeen isbeddellada firfircoon ee geeddi-socodka sida isbeddellada sare-u-qaadista. Intaa waxaa dheer, faragelinta gacanta waxay u horseedi kartaa waxtarla'aan, isticmaalka tamarta sare, iyo korodhka qashinka alaabta. Iyadoo la qaadanayo xeeladaha xakamaynta crystallization ee ay taageerto la socodka wakhtiga dhabta ah, warshadaha dawooyinka ayaa ka gudbi kara caqabadahan, gaaritaanka waxtarka weyn iyo kaydinta kharashka.

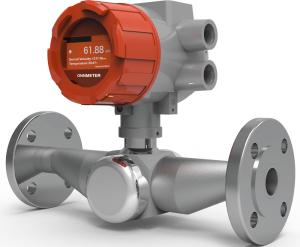

Qiyaasta Khadka Khadka ee Lonnmeter ee Hagaajinta Hannaanka Crystallization

La-qabsiga PLC ama Nidaamyada DCS ee Xakamaynta-Waqtiga-dhabta ah

Ku biirista aan kala go'a lahayn ee PLC ama nidaamka DCS ayaa wax ka beddeshay la socodka iyo xakamaynta habka crystallization warshadaha, taasoo awood u siinaysa la socodka wakhtiga dhabta ah ee cabbiraadaha habka muhiimka ah sida xoogga saarista iyo heerkulka. Farsamooyinkani waxay awood u siinayaan soosaarayaasha inay la socdaan cabbirka crystal, qaabka, iyo polymorphism iyagoon joojin wax soo saarka, hubinta tayada joogtada ah. Intaa waxaa dheer, nidaamka xakamaynta caqli-galku wuxuu u oggolaanayaa hagaajinta saxda ah ee heerkulka, halabuurka dareeraha, iyo heerarka isku-darka, hagaajinta habka oo dhan.

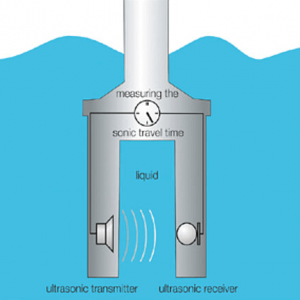

Faa'iidooyinka Ultrasonic Crystallization Monitoring

Kormeerka crystallization Ultrasonic waxay u taagan tahay awooddeeda aan fiicneyn, ee saxda ah ee saxda ah. Dareemayaasha fiirsashada Ultrasonic waxay cabbiraan xawaaraha hirarka dhawaaqa iyada oo loo marayo dhexdhexaad dareere ah, oo isku xidha cabbirradan xoogga saarista iyo sifooyinka crystal. Farsamadani waxay aad uga fiican tahay jawiga firfircoon, iyadoo bixisa xogta waqtiga-dhabta ah oo leh waqtiyada jawaabta ugu hooseeya hal ilbiriqsi. Si ka duwan hababka dhaqameed, kormeerka ultrasonic ma saameynayso arrimo sida midabka dareeraha ama dhaqdhaqaaqa, taas oo ka dhigaysa mid ku habboon hababka dawooyinka adag.

Farsamooyinka Ultrasonic ayaa sidoo kale kor u qaadaya nucleation iyo koritaanka crystal by soo jiidashada cavitation, taas oo abuurtaa supersaturation labis ah iyo yaraynaysaa wakhtiga induction. Tani waxay keenaysaa cabbirka crystall-ka iyo qaab-dhismeedka, oo muhiim u ah codsiyada dawooyinka sida crystallization lactose ama soosaarka API.

Faa'iidooyinka korjoogteynta crystallization ultrasonic waxaa ka mid ah:

- Xogta-Waqtiga-dhabta ah: Jawaab celin degdeg ah oo ku saabsan xaaladaha habsocodka, taasoo awood u siinaysa hagaajinta degdega ah.

- Saxnaanta Sare: Qiyaasta saxda ah ee feejignaanta iyo guryaha crystal, oo leh heerar sax ah oo gaaraya ± 0.05 m / s ee xawaaraha ultrasonic.

- Hawlgalka aan Duulaanka ahayn: Looma baahna muunad, yaraynta khataraha faddaraynta iyo wakhtiga dhimista.

- Kala duwanaansho: Ku habboon hababka kala duwan ee daawooyinka, laga bilaabo R&D-yar-yar ilaa wax-soo-saarka baaxadda leh.

Iyadoo la isku darayomitirka feejignaanta gudahaNidaamyada crystallization, saarayaasha ayaa gaari kara xakamaynta crystallization taas oo kordhisa wax-soo-saarka, yaraynaysaa isticmaalka tamarta, oo hubisa u hoggaansanaanta sharciga.

Codsiyada wax ku oolka ah ee Soo saarista Dawooyinka

Hagaajinta Lactose crystallization

Soo saarista dawooyinka, laktoosku waxa caadi ahaan loo isticmaalaa dawooyinka kiniiniga ah. Xakamaynta geeddi-socodkeeda crystallization waa lagama maarmaan si loo hubiyo cabbirka walxaha joogtada ah iyo milanka. Nidaamyada la socodka crystallization ee daawada, gaar ahaan kuwa isticmaalaya tignoolajiyada ultrasonic, ayaa si guul leh loo hirgeliyay si loola socdo crystallization lactose waqtiga dhabta ah.

Xaqiijinta Xakamaynta Polymorphism

Polymorphism, awoodda isku-darka inay ku jiraan qaabab badan oo crystals ah, ayaa ah arrin muhiim u ah soo saarista dawooyinka. Noocyada kala duwan ee polymorphs waxay saameyn karaan heerka milanka daawada iyo helitaanka noolaha. Kormeerka Crystallization via Lonnmeter mitirka fiirsashada ultrasonic caawin aqoonsiga iyo xakamaynta foomamka polymorphic waqtiga dhabta ah. Iyadoo la ilaalinayo xaaladaha ugu wanaagsan,kormeeraha nidaamka inlinewaxay hubisaa in polymorph-ka la rabo si joogto ah loo soo saaro, taasoo yaraynaysa halista dufcaddii guuldarraysatay iyo dib-u-shaqayn qaali ah.

Su'aalaha Guud ee Ku Saabsan Kormeerka Crystallization (FAQs)

Waa maxay Doorka Kormeerka Crystallization ee Dawooyinka?

La socodka crystallization ee dawooyinka waxay hubisaa soosaarka joogtada ah ee API-yada leh guryaha la rabo, sida nadiifnimada, cabbirka crystal, iyo polymorphism. Bixinta xogta waqtiga-dhabta ah, qalabka la socodka sida dareemayaasha ultrasonic iyo nidaamyada PAT waxay caawiyaan soosaarayaasha ilaalinta xaaladaha habka ugu wanaagsan, yareeyaan kala duwanaanshaha, iyo hubinta u hoggaansanaanta heerarka sharciyeynta.

Sidee U Korjoogteynta Crystallization Ultrasonic u wanaajisaa waxtarka?

Kormeerka crystallization Ultrasonic waxay kor u qaadaysaa waxtarka iyadoo la siinayo aan-ka-hortagga, cabbiraadaha waqtiga-dhabta ah ee feejignaanta iyo guryaha crystal. Waxay yaraynaysaa wakhtiga kicinta, waxay yaraynaysaa isticmaalka tamarta, waxayna ka hortagtaa fashilka dufcaddii iyada oo awood u siinaysa kontoroolka saxda ah ee nukleation-ka iyo korriinka crystal.

Waa maxay faa'iidooyinka Kharashka ee Xakamaynta Crystallization-Waqtiga-dhabta ah?

Xakamaynta habka crystallization-waqtiga-dhabta ah waxay yaraynaysaa qashinka walxaha, isticmaalka tamarta, iyo wakhtiga dhimista, taasoo horseedaysa kayd qiimo badan.

Habka crystallization-ka ee kormeerka iyo xakamaynta ayaa ah beddelka wax-soo-saarka dawada, oo bixisa saxnaanta iyo hufnaanta aan la barbar dhigi karin. Xakamaynta crystallization iyada oo loo marayo xogta waqtiga-dhabta ah kaliya ma wanaajiso tayada alaabta laakiin sidoo kale waxay hagaajinaysaa hawlaha, taas oo ka dhigaysa maalgashi muhiim ah warshad kasta oo dawooyinka ah.

La xidhiidh kooxdayada maanta si aad u sahamiso xalalka korjoogteynta crystallization ultrasonic ee horumarsan ee ku habboon baahiyahaaga. Booqo mareegahayaga si aad u hesho la tashi bilaash ah oo ogow sida kormeerka-waqtiga dhabta ah uu sare ugu qaadi karo waxtarkaaga iyo tayadaada wax soo saarka.

Waqtiga boostada: Jul-03-2025